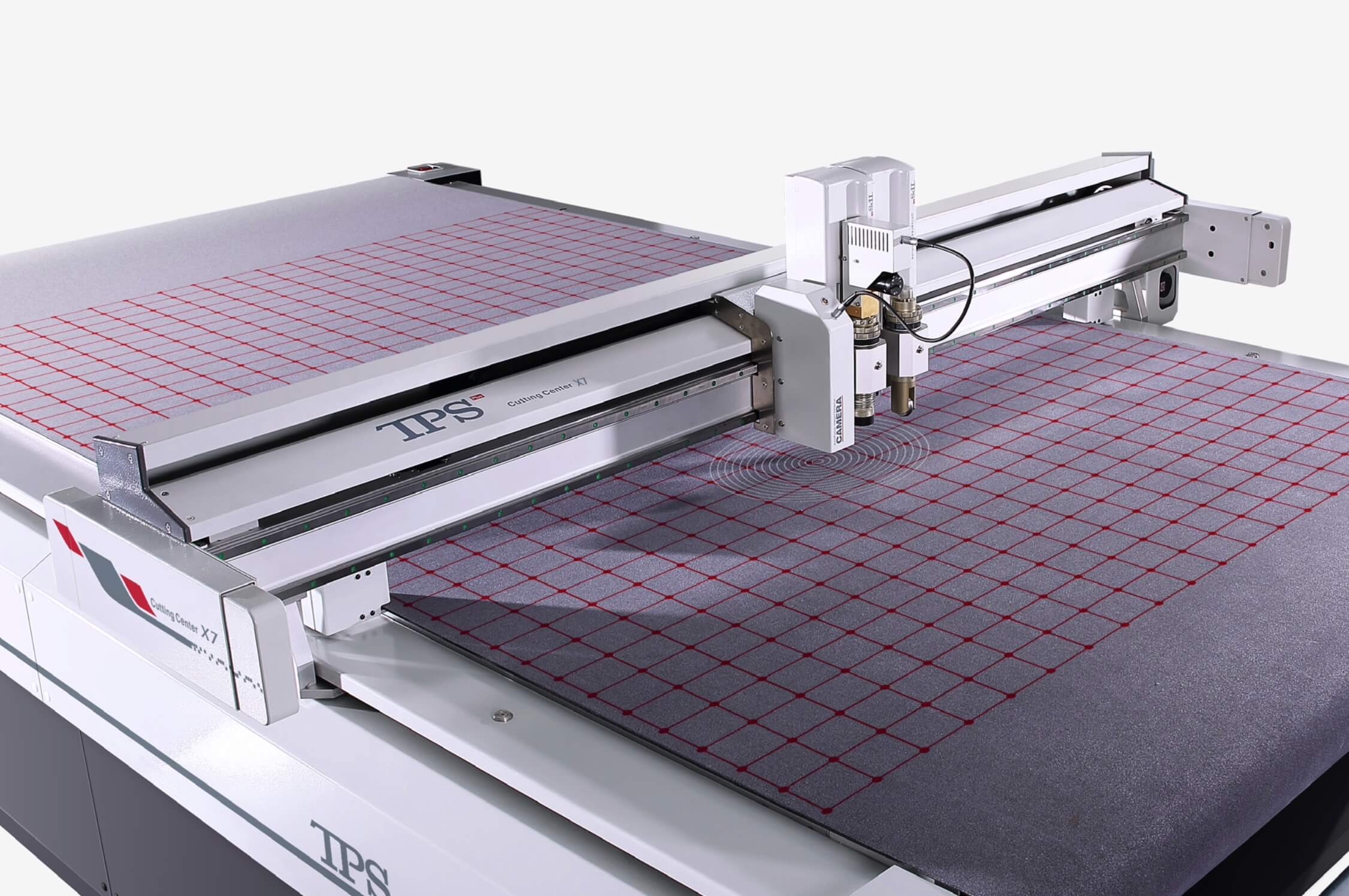

TPS X7 Digital Cutting Machine

The TPS X7 is the standard workhorse perfect for businesses of all sizes. This cutting machine focuses on the intelligent cutting of non-metallic material into different designs. It can quickly complete various operations, such as full-cutting, half-cutting, boring and milling, punching, creasing, and marking, easily solving production efficiency problems like those found in sample-making and small batch production.

Powerful and flexible

The TPS X7 allows print service providers to greatly boost the productivity of their postpress departments. This cutting system easily integrates into existing production environments, providing a clear competitive advantage in markets where maximum productivity is required.

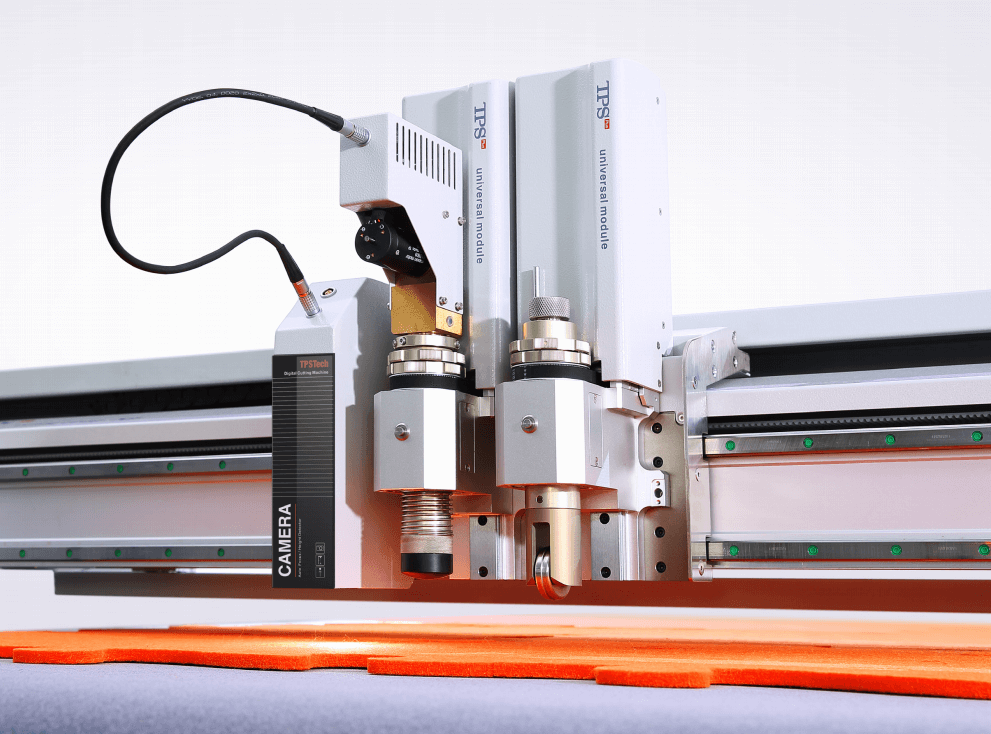

Universal Module

The Universal Module supports a range of interchangeable tools for cutting, creasing, and marking diverse materials like rubber, foam, cardboard, textiles, and plastics—ideal for workshops needing quick tool changes.

Tools

Independent milling system

The router module is a high-performance, high-frequency spindle. Depending on your applications and requirements, versions from 350W to 1800W are available. It supports milling up to 60,000 RPM and is mainly used to cut acrylic, MDF, ABS plates, and other hard materials. The router module includes an imported spindle and a vacuum cleaning system.

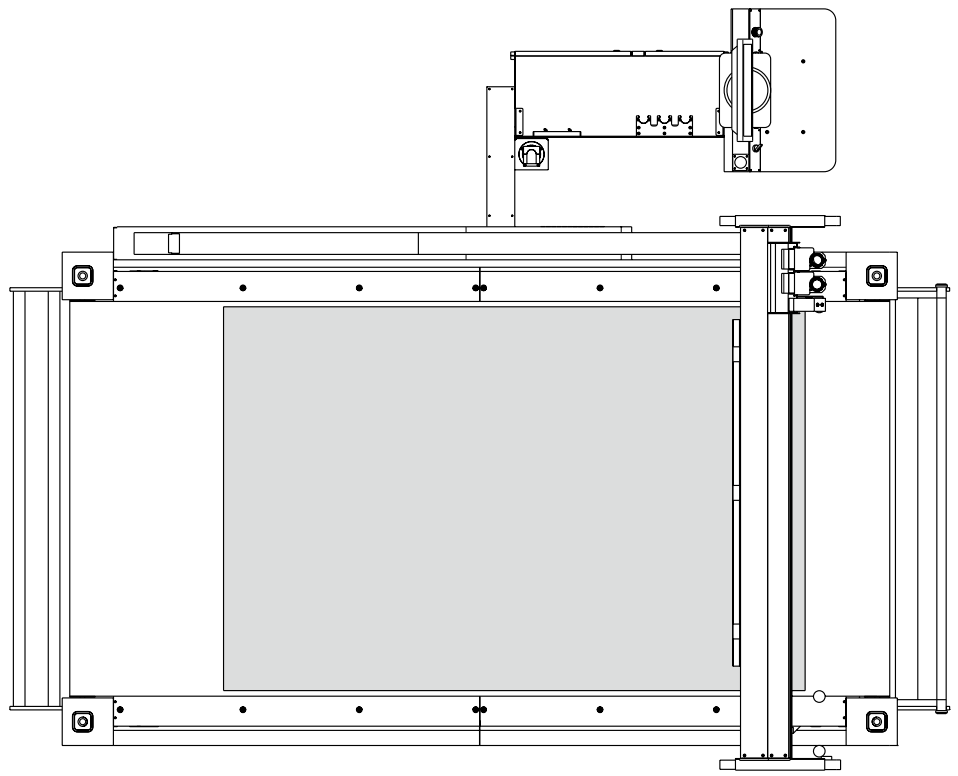

Precision-Welded Frame

The cutter's frame is built to heavy-duty, industrial-grade standards. The assembly process involves pre-welding treatment, machine welding, and post-welding heat sealing under strict quality control for the strongest and most durable frame possible.

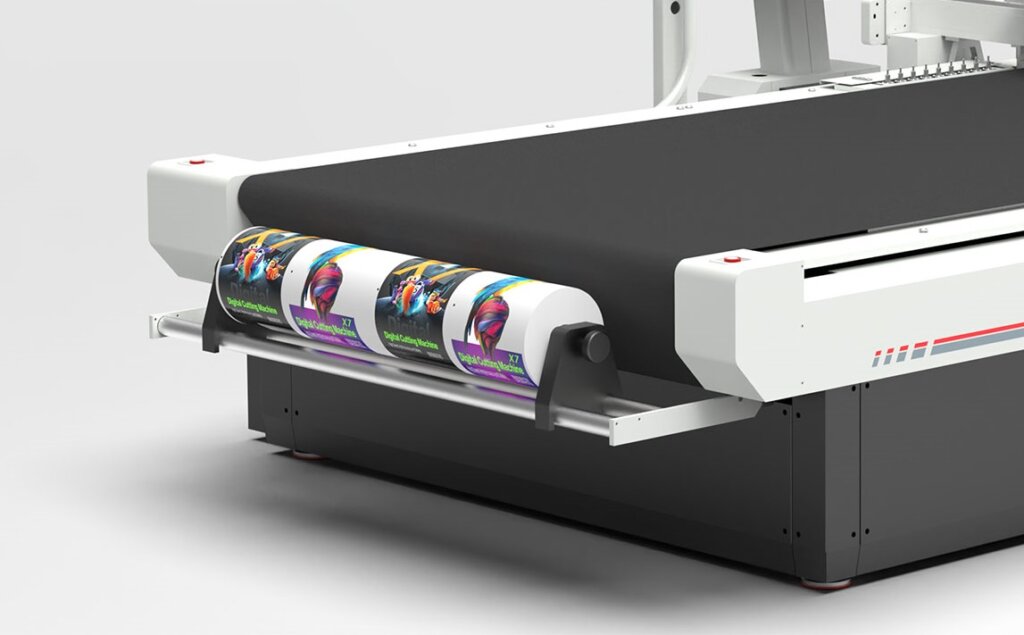

Roll Feed Module

A mechanism for smooth feeding of roll materials designed to improve overall cutting efficiency. The conveyer belt combines flawlessly with the feeder module to streamline production.

Operator Station

The mobile computer station makes operating the cutter more ergonomic and convenient. It is equipped with an emergency stop button and holders for tool attachments.

Conveyor Feeding System

The cutting mat is a belt that forms a closed loop around pulleys so it can continually rotate, allowing continuous automatic material feeding and making the cutting length essentially unlimited.

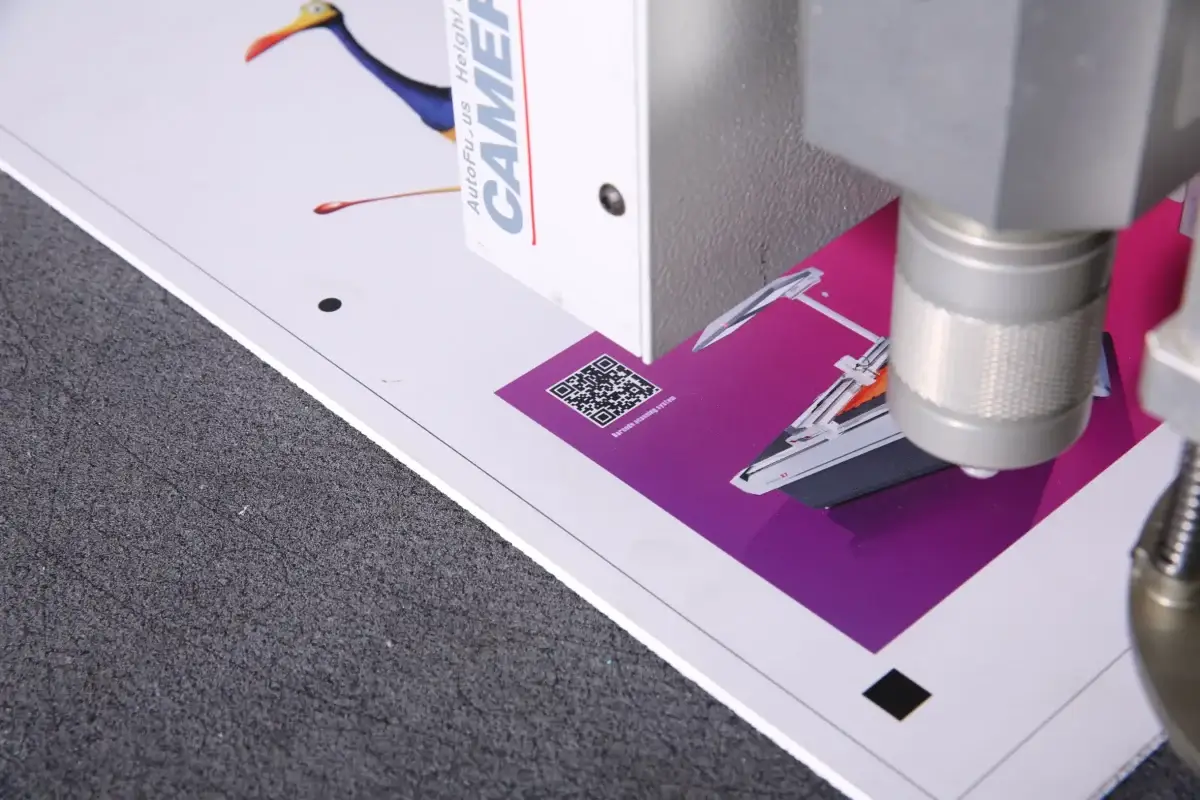

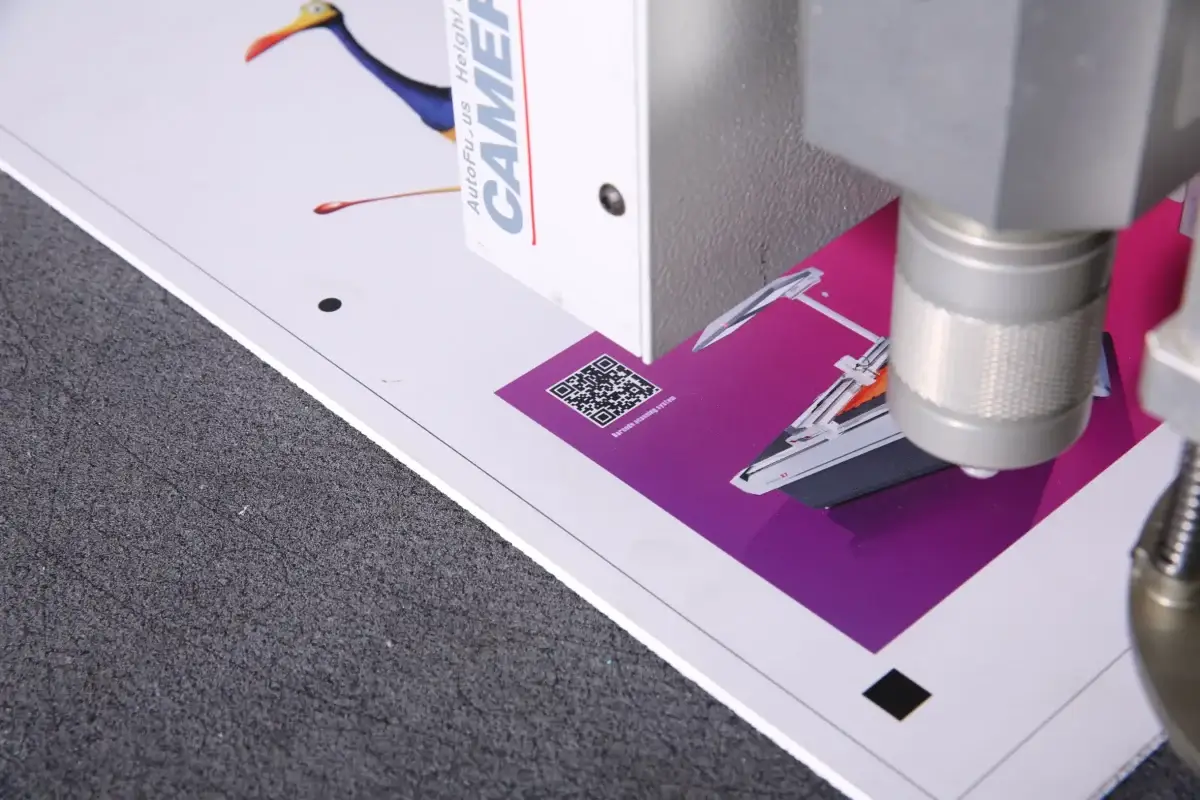

File Management System

The TPS X7 CAM software for the sealing industry offers comprehensive management of processed documents—including file names, times, quantities, materials, batches, and more. It can generate barcodes or QR codes, enabling fast retrieval of files by scanning. This streamlines future repeat processing, while historic file management significantly simplifies user operations.

Working Area

The TPS X7 has a working area of 1600 mm x 2500 mm, which is large enough to handle most of the cutting and milling needs of medium-sized businesses.

Technical Specifications

Features of the TPS X7 cutter

Material Holder

The holder is a simple mechanism located at the front of the cutter used to collect loose cut material. It helps quickly separate finished products from scraps.

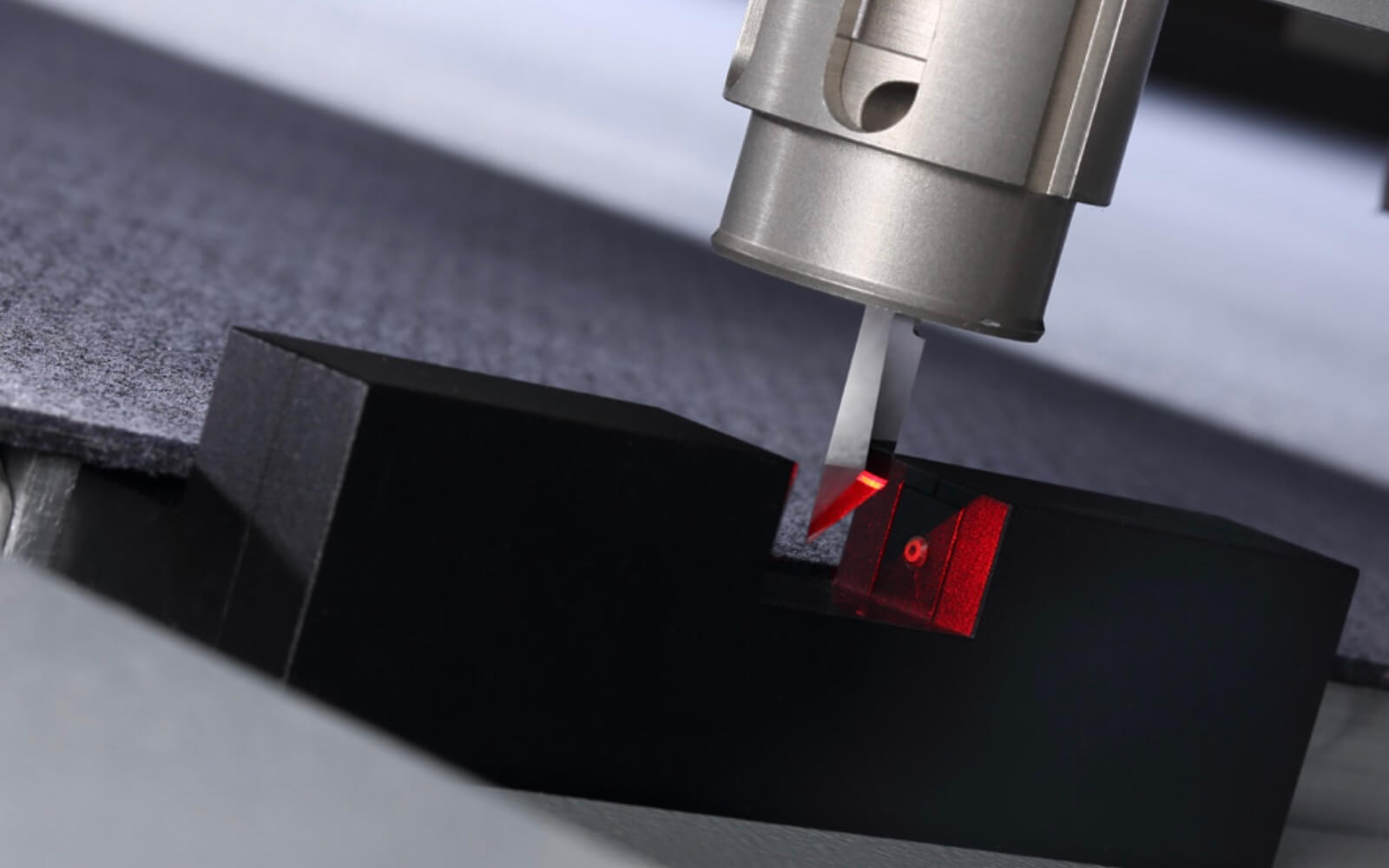

Reverse Thrust Air Cushion

Thrust reverse valves built into the table's vacuum system create an air cushion that helps move roll or rigid media smoothly along the table. The unique air cushion technology also minimizes registration mark capture errors.

Precision-Welded Frame

The cutter's frame is built to heavy-duty, industrial-grade standards. The assembly process involves pre-welding treatment, machine welding, and post-welding heat sealing under strict quality control for the strongest and most durable frame possible.

Vacuum Pump Control System

The TPS cutter's powerful vacuum pump ensures a powerful table grip on all types of media, while its proprietary control software is conveniently managed using the built-in computer system.

Advanced Servo Amplifier Drive

The dedicated amplifier supports a 2 kHz response speed and with a 150 Mbps optical network connection offers the shortest takt times possible. The servo motor is equipped with a high-resolution encoder for ultrafine accuracy, and the large capacity capacitor allows regenerative energy to be used efficiently, reducing energy consumption.

Linear Guideway Rails

Linear guideways provide extremely low-friction movement able to take loads in all directions. This feature is designed to achieve high precision and greatly enhanced moving accuracy.

Roll Feed Module

A mechanism for smooth feeding of roll materials designed to improve overall cutting efficiency. The conveyer belt combines flawlessly with the feeder module to streamline production.

Modern Computer System

A complete workstation for operating TPS software. Includes performance components, a 4K monitor, and the latest Windows operating system.

TPS Software

The included TPS software offers several useful features, including material irregularity compensation, automatic edge and positioning detection, serif avoidance, multi-tasking, and multi-position cycle cutting.

Conveyor Feeding System

The cutting mat is a belt that forms a closed loop around pulleys so it can continually rotate, allowing continuous automatic material feeding and making the cutting length essentially unlimited.

6-Zone Vacuum Bed

The industrial-strength aluminum honeycomb vacuum table with independent 6-zone vacuum system guarantees perfect flatness for all media types. The conveyor belt is made of durable 4mm-thick felt with excellent permeability and good wear resistance for a long service life. The table comes with a powerful vacuum pump for superior downward pressure to ensure no movement during operations.

Configurator

Preset Configuration

Modules

Select the modules suited to your materials and workflow.

Options

Select additional options to enhance your cutter configuration.

Tools

Select the cutting tools designed for your specific materials and applications.

Configuration

Configuration Request

Gallery

Request a quote or ask a question

We'd love to help! Contact us to learn more about cutter, schedule a demonstration, or ask us anything else you'd like to know.