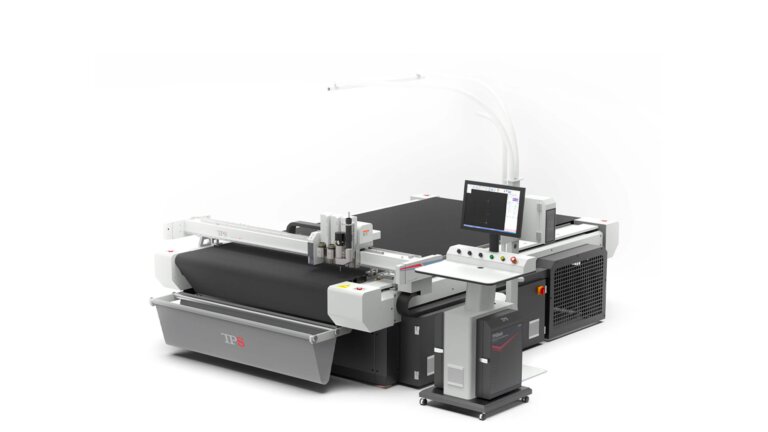

TPS S3 Flatbed Digital Cutting Machine

The TPS S3 Digital Auto-Feed Flatbed Cutter adheres to the design concepts of speed, stability, intelligence, environmental protection, and maximal efficiency. It is widely used in digital printing, offset printing, advertising packaging, signage production, composite material processing, and many others.

from $39,703

Cutter configurator

We offer pre-configured cutter that you can expand based on your business needs.

Configuration

TPS S3

Total

Specifications

Working Area Width

Bed size 4.2'x3.2' (1300x1000mm)

Power Consumption

5kW

Vacuum Pump Power

1.5kW

Voltage

220V 60Hz/50Hz

Max Media Width

1300x1000mm

Max Media Thickness

<10 mm

Portal Height

60 mm

Max Processing Speed

72 m/min

Quantity of Servomotors

6 pcs

Net Weight

660 kg

Dimensions

2200x1710x1250mm