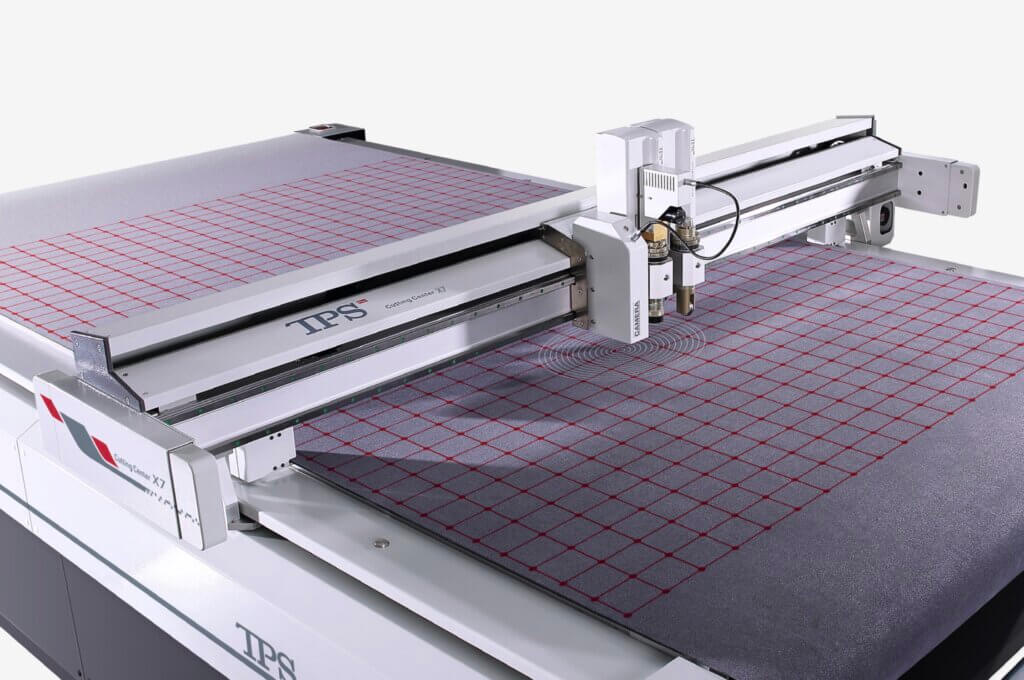

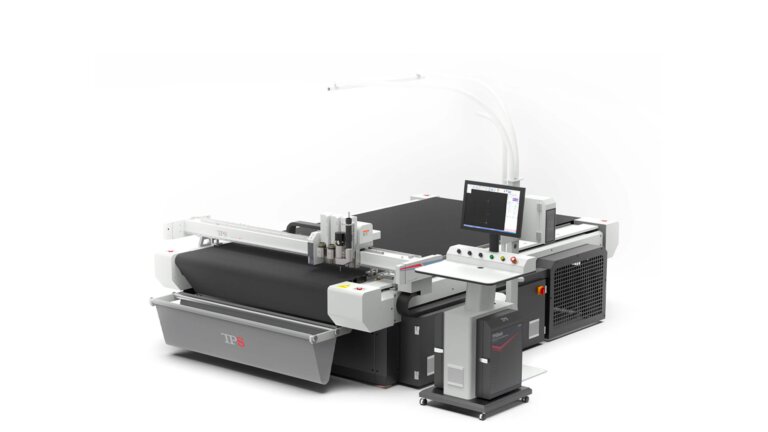

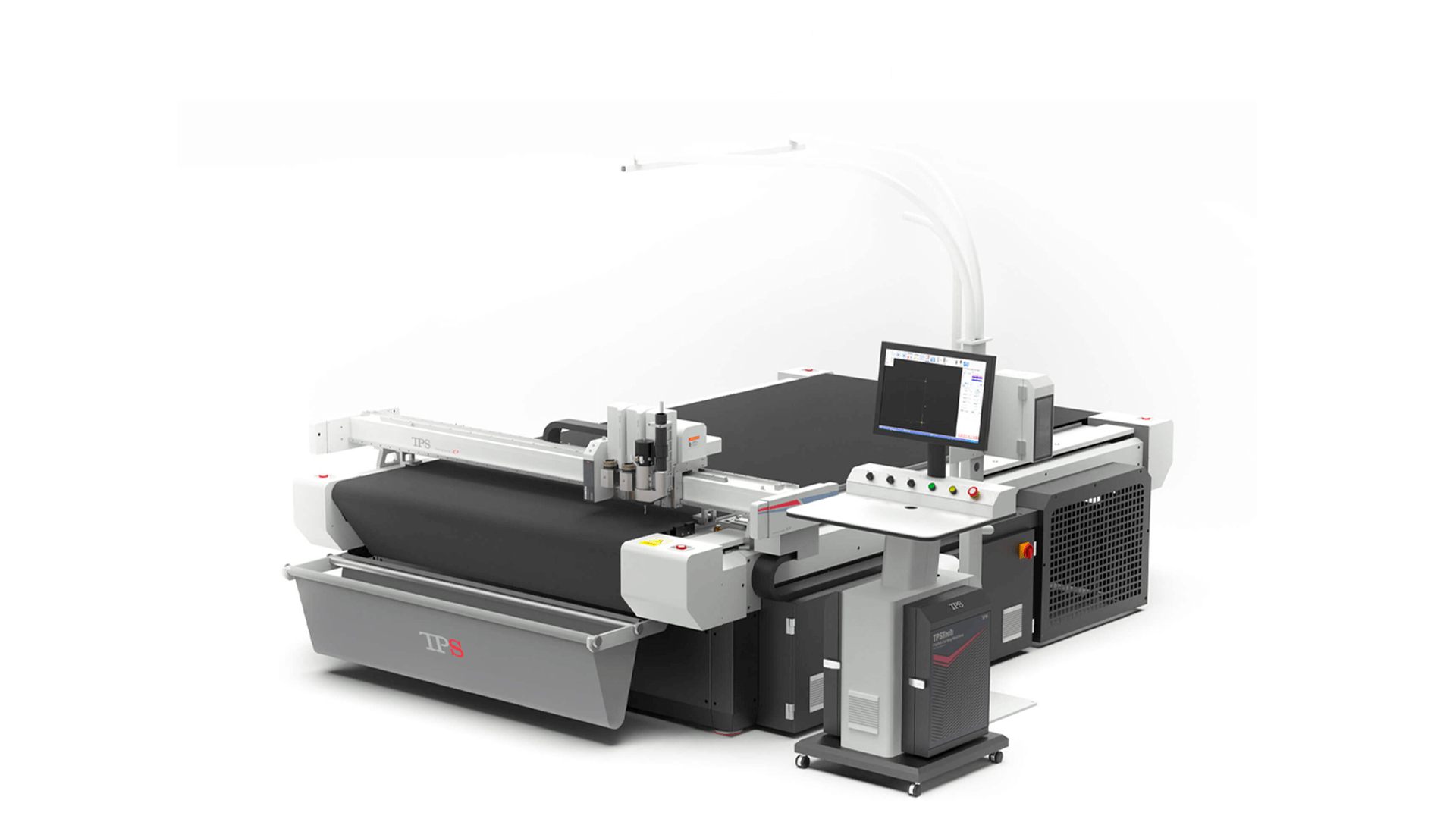

TPS X9 XL Flatbed Digital Cutting Machine

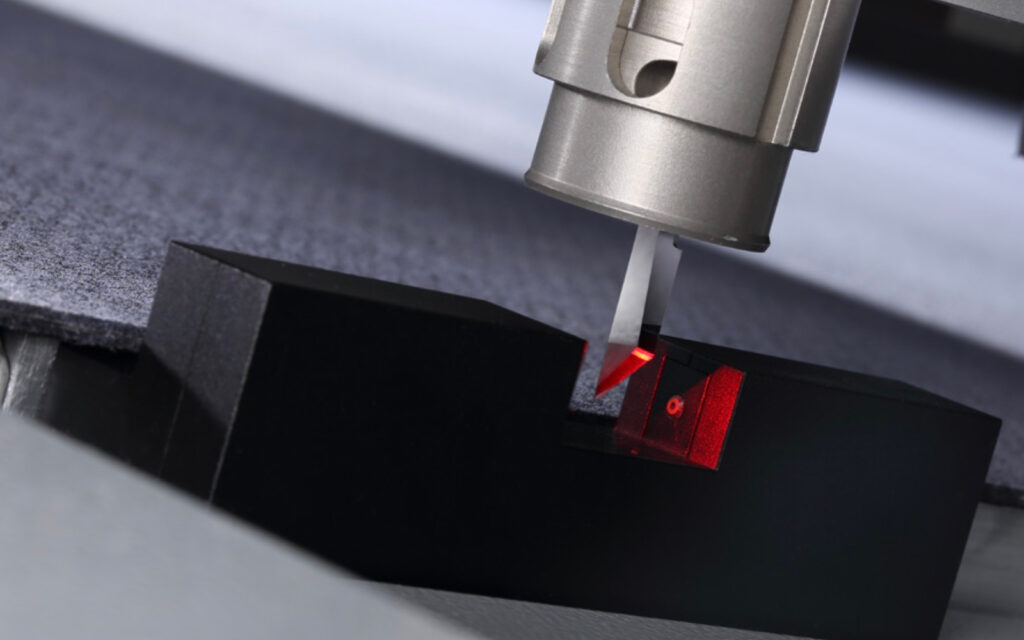

With the largest table size available from TPS, the X9 XL is best suited for the widest materials available on the market. It focuses on the intelligent cutting of non-metallic material into different designs. It can quickly complete various operations, such as full-cutting, half-cutting, boring and milling, punching, creasing, and marking, easily solving production efficiency problems like those found in sample-making and small batch production.

from $66,415

Cutter configurator

We offer pre-configured cutter that you can expand based on your business needs.

Configuration

TPS X9 XL

Total

Specifications

Working Area Width

Bed size 10.4'x8.2' (3200mmx2500mm)

Power Consumption

2.5kW

Vacuum Pump Power

7.5/8.6kW

Voltage

380V

Max Media Thickness

35mm

Portal Height

60mm

Max Processing Speed

72m/min

Quantity of Servomotors

6pcs for 2 cutting heads, 7pcs for 3 cutting heads

Net Weight

1500kg

Dimensions

4040x3273x2630mm